Launch

Vision

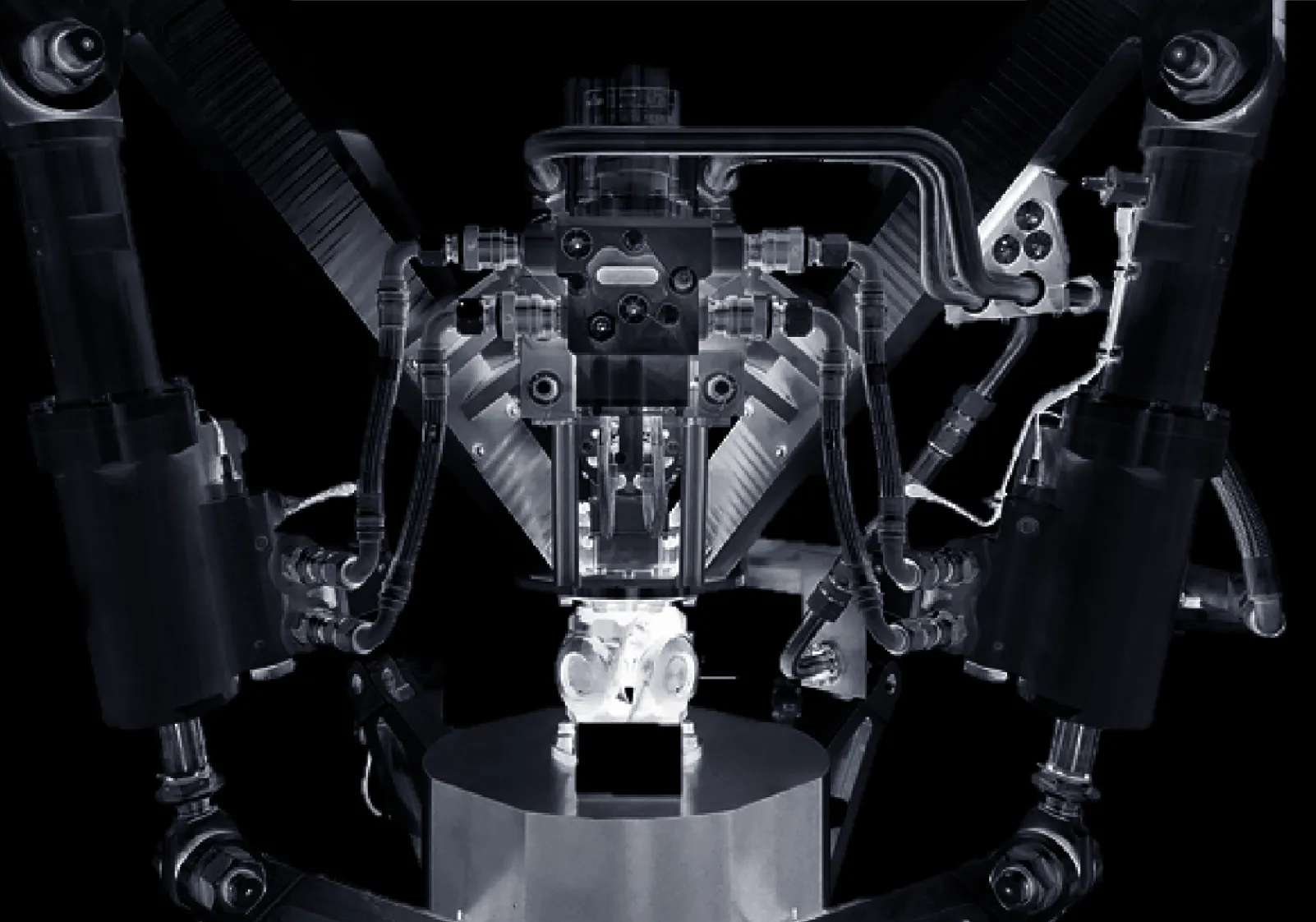

The success of Nuri added Korea as the world's 7th to have

developed a launcher capable to carry payloads over a ton

Korea has entered the era of New Space

Liftoff! K-Space

Hanwha will lead Korea, once the late comer to

global space race,

to develop its homegrown launch

capabilities and guide mankind toward a better future

with combined synergy under Space Hub.

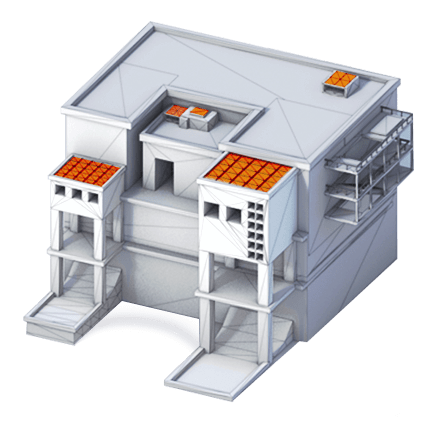

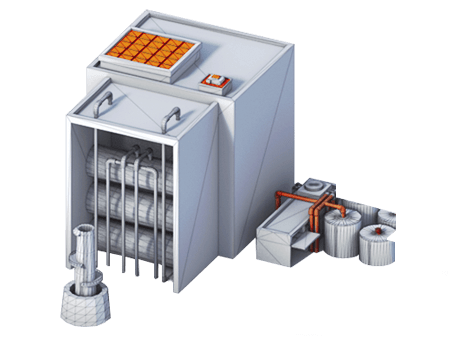

"the scene of the 1st test launch of Nuri (KSLV-II)."